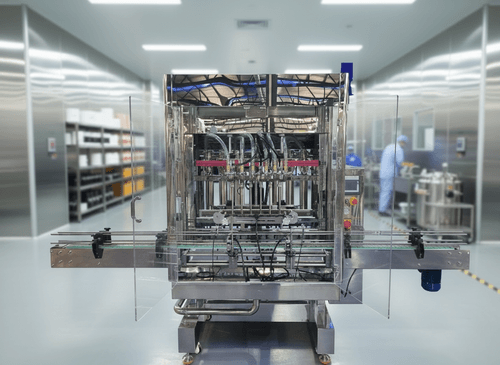

KFM-6 6-Head Fully Automatic Linear Filling Machine

$25,000.00

Key Features

High throughput: six synchronized filling heads enable fast, continuous filling with minimal downtime.

Precision dosing: servo-driven or piston dosing options (model-dependent) provide accurate volume control and excellent repeatability.

Fully automatic linear design: smooth product flow and straightforward integration into existing production lines.

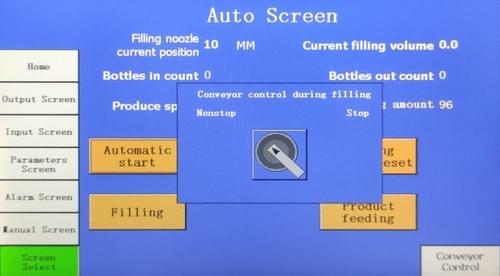

User-friendly HMI: touch-screen control with programmable filling recipes, easy setup, and quick changeover.

Sanitary construction: stainless steel (SUS304/316 as required) contact parts, CIP-compatible design for easy cleaning and compliance with GMP.

Adjustable filling speed & volume: customizable to accommodate a wide range of product viscosities from watery liquids to light creams.

Anti-drip & vacuum return: built-in anti-drip valves and vacuum return systems reduce waste and ensure clean production.

Safety & reliability: emergency stop, safety guards, and stable frame reduce operator risk and extend machine life.

Optional accessories: capping, labeling, conveyor integration, heating tanks, air-operated components, and PLC upgrades.

Technical Specifications (typical)

Filling heads: 6 Filling range: 5 ml — 1000 ml (model/configuration dependent)

Filling accuracy: ±0.5% — ±1.5% (depending on product and model)

Filling speed: up to 1200–3600 bottles/hour (depending on bottle size and product)

Power supply: 220V/380V, 50/60Hz (customizable) Air pressure: 0.6–0.8 MPa (for pneumatic components)

Machine frame: Stainless steel SUS304 (optionally SUS316)

Control system: PLC + touch-screen HMI

Dimensions & weight: customizable per configuration

Applications

Pharmaceuticals: syrups, suspensions, oral liquids

Food & beverage: juices, sauces, dressings, edible oils

Cosmetics & personal care: shampoos, lotions, serums

Chemicals: detergents, cleaning solutions, industrial liquids

Advantages

Increased productivity with synchronized 6-head filling

High-precision dosing reduces material waste and cost Hygienic design simplifies cleaning and conforms to industry standards

Flexible configuration supports a wide variety of bottle types and liquid viscosities

Easy operation and fast changeover minimize labor requirements

Why choose KFM-6

The KFM-6 combines speed, accuracy, and sanitary design to meet the needs of modern production lines. Its modular design and optional accessories allow manufacturers to build a tailored filling solution that scales with production demand while maintaining product quality and regulatory compliance.

For pricing, custom configurations, or to request a quotation and technical drawings, please provide your product type, target filling volume, container type, and desired hourly output.